Casting technologies

Casting TechnologiesExplore advanced casting technologies for efficient production solutions.In modern manufacturing, casting technology is a key process for creating complex parts. With the continuous advancement of technology, traditional casting processes combined with emerging technologies have brought higher efficiency, lower costs, and superior quality to industrial production. On this page, we will introduce three cutting-edge casting technologies: Graphite Mold Process, Lost Wax Precision Casting, and 3D Printed Sand Casting.

1. Graphite Mold Process

The Graphite Mold Process is a casting technology that uses graphite materials to create molds. Graphite’s unique physical and chemical properties make it an ideal choice for producing high-quality castings.

Process Features

• High Thermal Conductivity: Graphite quickly conducts heat, ensuring uniform cooling of the metal in the mold cavity and reducing casting defects.

• Low Thermal Expansion: At high temperatures, graphite has a very low thermal expansion coefficient, ensuring the dimensional accuracy of the castings.

• Good Chemical Stability: Graphite is chemically stable with most molten metals, preventing reactions.

• Reusable: Graphite molds can be reused after simple cleaning, reducing production costs.

Application Scenarios

The Graphite Mold Process is widely used in the production of large and complex castings, such as mechanical parts, molds, and aerospace components. It is particularly suitable for applications requiring high dimensional accuracy and surface quality.

Advantages

• High Precision: Capable of achieving high-precision replication of complex shapes.• High Efficiency: Reduces production cycles and increases production efficiency.• Environmentally Friendly: Graphite materials can be recycled, reducing waste emissions.

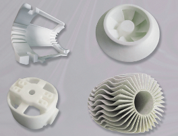

2. Lost Wax Precision Casting

Lost Wax Precision Casting is a precision casting technology that requires little or no machining. Also known as investment casting, it involves creating a wax model, coating it with a high-temperature ceramic material, and then melting the wax to create a cavity for metal pouring.

Process Steps

1. Wax Model Making: Create a wax model with the same shape as the final casting using manual carving or wax injection.

2. Assembling: Connect multiple wax models into a “tree” structure for batch production.

3. Ceramic Shell Coating: Apply ceramic material multiple times to form a sturdy shell.

4. Wax Melting: Heat to melt the wax out of the shell, leaving a cavity.

5. Sintering and Preheating: Strengthen the ceramic shell and stabilize it.

6. Pouring: Pour molten metal into the cavity.

7. Cleaning: Remove residual material to obtain the finished product.

Application Scenarios

Lost Wax Precision Casting is widely used in jewelry making, aerospace parts, and automotive components. It is particularly suitable for producing small parts with complex shapes and high precision requirements.

Advantages

• High Precision: Capable of achieving micrometer-level dimensional accuracy.

• Complex Shape Replication: Can produce complex internal structures and surface details.

• Good Surface Finish: Reduces the need for subsequent machining, lowering production costs.

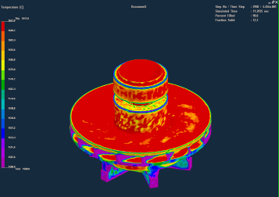

3. 3D Printed Sand Casting

3D Printed Sand Casting is an innovative method that combines 3D printing technology with traditional casting processes. It directly creates casting molds or prototypes using 3D printing, eliminating the need for traditional mold making and significantly reducing production time and cost.

Process Steps

1. Design: Use CAD software to design a 3D model.

2. Printing: Create a prototype or mold using a 3D printer.

3. Post-processing: Sand and cure the printed part as needed.

4. Pouring: Pour molten metal into the printed mold.

5. Cleaning: Remove the mold to obtain the finished product.

Application Scenarios

3D Printed Sand Casting is suitable for rapid prototyping, small batch production, and complex part manufacturing. It is particularly suitable for industries that require rapid design iteration and production.

Advantages

• Rapid Prototyping: Significantly reduces the time from design to finished product.

• No Mold Required: Eliminates the cost and time of traditional mold making.

• Complex Structure Manufacturing: Capable of producing structures that are difficult for traditional processes.

• High Flexibility: Quickly adjust design and production according to customer needs.

| Comparison Dimension | Graphite Mold Process | Lost Wax Precision Casting | 3D Printed Sand Casting |

|---|---|---|---|

| Process Principle | Using graphite molds for metal pouring. | Creating wax models, coating with ceramic shell, melting wax, and pouring metal. | Directly creating molds or prototypes with 3D printing and pouring metal. |

| Dimensional Precision | High precision, suitable for complex shapes, accuracy up to ±0.2mm. | High precision, suitable for complex shapes, accuracy up to ±0.1mm. | Medium-high precision, suitable for complex shapes, accuracy up to ±0.3mm. |

| Surface Quality | Good surface finish, suitable for high precision requirements. | Excellent surface finish, suitable for high precision requirements, can be directly plated or painted. | Medium surface finish, requires minimal post-processing. |

| Production Efficiency | Moderate, suitable for medium and small batch production. | Low, suitable for medium and small batch production, complex process. | High, suitable for rapid prototyping and small batch production. |

| Mold Cost | Moderate, graphite molds can be reused. | High, ceramic shells require multiple coatings, high mold cost. | Low, no traditional molds required, 3D printing cost is controllable. |

| Unit Cost | Moderate, suitable for complex castings. | High, suitable for high precision complex castings. | Low, suitable for rapid iteration and small batch production. |

| Applicable Materials | Cast steel, cast iron, aluminum alloy, etc. | Cast steel, cast iron, aluminum alloy, stainless steel, etc. | Cast steel, cast iron, aluminum alloy, etc. |

| Applicable Scenarios | Large complex castings, such as mechanical parts, molds. | Precision small castings, such as jewelry, aerospace parts. | Rapid prototyping, small batch complex castings. |

| Advantages | High thermal conductivity, low thermal expansion, reusable. | High precision, strong complex shape replication ability, high surface finish. | Rapid prototyping, no molds required, low cost, strong complex structure manufacturing ability. |

| Disadvantages | Longer production cycle, complex mold making. | Complex process, high cost, low production efficiency. | High 3D printing equipment cost, limited for large castings. |

| Environmental Friendliness | Graphite can be recycled, environmentally friendly. | Environmentally friendly, but complex process requires handling of waste wax and ceramic shells. | Environmentally friendly, reduces mold waste. |