Pulp and Paper

The pulp and paper industry, with its intricate production processes and demanding operational conditions, requires equipment that can withstand high – stress environments, including exposure to corrosive chemicals and high – humidity. ALBA, leveraging its expertise in titanium and zirconium casting, offers a comprehensive range of products tailored to meet the unique needs of this industry.

Our Product Range

- Turbine Impellers

Our turbine impellers, crafted from high – quality titanium, are designed to excel in the pulp and paper manufacturing environment. Titanium’s remarkable strength – to – weight ratio allows the impellers to operate at high rotational speeds, efficiently converting the energy of steam or other working fluids into mechanical power. This results in enhanced power generation for various processes within the mill, such as driving pumps and blowers.

The corrosion – resistant property of titanium is a significant advantage. In pulp and paper production, where the working fluids may contain acidic or alkaline substances, our titanium impellers can resist corrosion over extended periods. This not only extends the service life of the impellers but also reduces maintenance and replacement costs, minimizing production downtime.

- Fluid Conveyance and Control Components

- Valves: Constructed from corrosion – resistant titanium and zirconium alloys, our valves are suitable for controlling the flow of a wide range of fluids in pulp and paper mills. These include aggressive chemical solutions used in pulping processes, as well as the various water – based slurries and effluents. Whether it’s a ball valve for quick – acting shut – off, a gate valve for full – flow or isolation applications, or a check valve to prevent backflow, our valves ensure reliable and leak – free operation, maintaining the integrity of the production process.

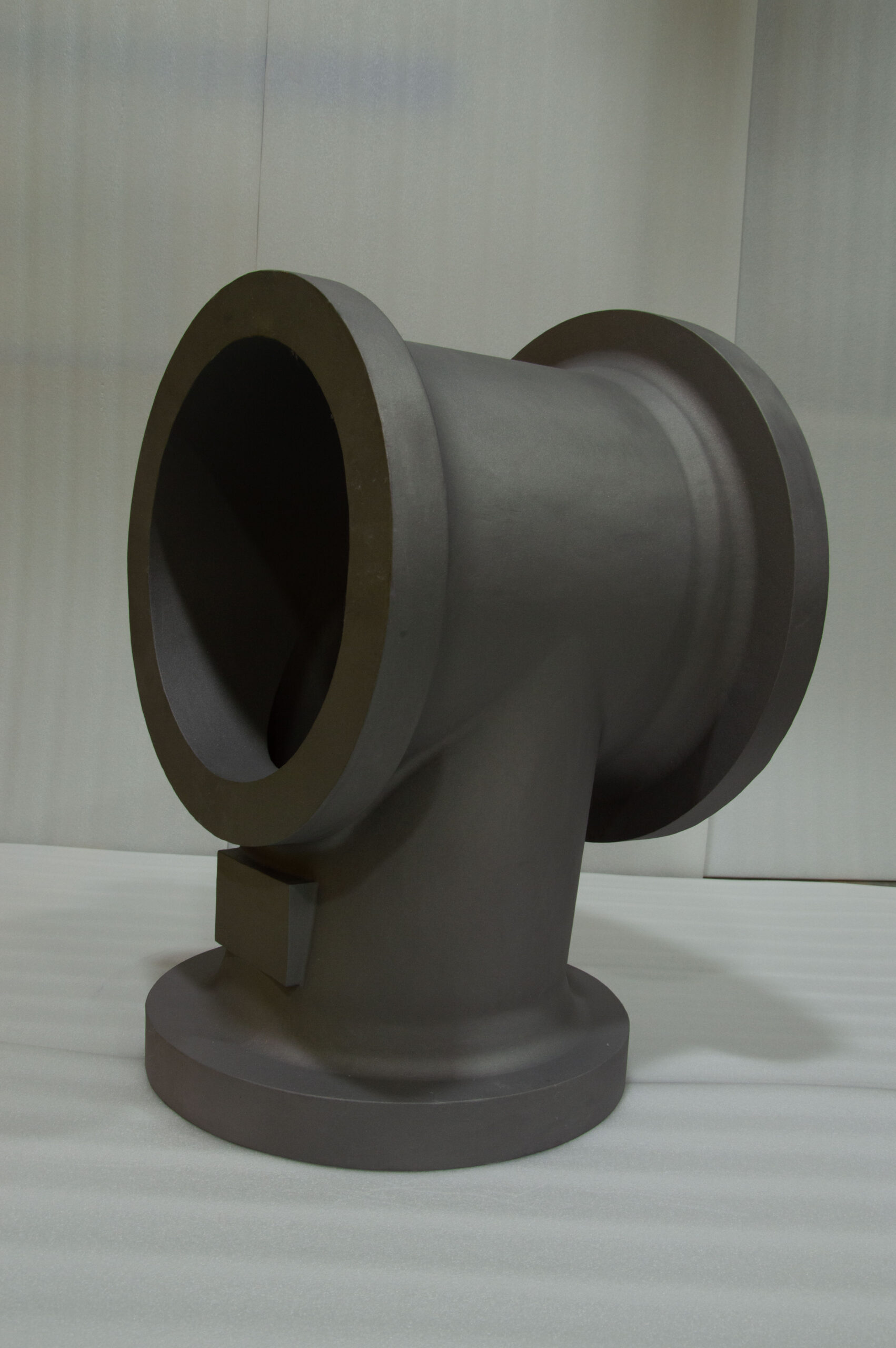

- Pipes and Fittings: Our titanium and zirconium pipes and fittings are engineered to handle the corrosive and abrasive fluids commonly encountered in the industry. They offer excellent resistance to the harsh chemicals used in pulping, such as sulfuric acid, sodium hydroxide, and chlorine – containing compounds. With their smooth inner surfaces, these pipes and fittings also minimize the risk of blockages and ensure efficient fluid flow, whether it’s for the transportation of cooking liquor, black liquor, or white water in the recycling systems.

- Custom – Engineered Castings

Understanding that each pulp and paper mill may have unique equipment requirements, we offer custom – engineered titanium and zirconium castings. Our team of experienced engineers collaborates closely with clients to design and manufacture components that precisely fit their specific machinery and production processes. Whether it’s a specialized component for a new – generation paper machine or a replacement part to improve the performance of an existing system, we can deliver tailored solutions that enhance overall equipment efficiency and productivity.